So, the motor I finished about a month ago ran excellent . . . for a hundred miles. I overheated it badly within the first fifty and was really worried that I'd fucked something up. Turns out the lifters had pumped up (and I misadjusted one) and it was easily fixed. Then a week or two later it became harder and harder to start. I checked EVERYTHING and came up lacking for ideas. I tested ignition, wiring, fuel flow, carb passages, etc. I did a leakdown and found 10% on the front and 5% on the rear. Not great, but I tested it cold (wouldn't start) and thought maybe the rings hadn't even really settled yet. Hardly anything enough to account for not starting . . . or so I thought.

After many frustrating theorizing and testing sessions, I decided to stop fucking around and take the top end off.

I'd missed enough nice late fall days.

Turns out the FUCKING PIECE OF SHIT HEADS FROM STD THAT I'VE HAD MANY PROBLEMS WITH had failed yet again.

The thread inserts started to pull from the castings.

Go ahead, tell me it's my fault. I'll just tell you that I'm the only person who has ever installed these heads and have used a torque wrench EVERY TIME, tightened in proper order, to 35, 45, 55, then 65 ft/lbs. Retorqued after a few heat cycles every time.

Rather than get all bummed out and suffer shop paralysis (too much to do, no time, deadline approaching) I started digging in the parts stash for the set of shovel heads I put up there about five or six years ago.

They were plenty crusty, although were in real nice running shape when I took them off.

But, have since moved to big-bore cyls since taking them off.

I felt fearless for some reason and tossed them on the B-port and had both of them cut perfectly (3.884") in about a half-hour. It sure is nice to have gotten enough experience from trial and error in the last couple years to be able to do something like this with confidence. The first time I cut on cases, I was sweating bullets and triple measured everything, and . . . if I were a praying man, would have consulted the heavens first.

Here's a few pics I snapped off in the last two days. I started this project three days ago and have been working after work for a few hours each night. I am DETERMINED to get this bike back up in runnning in time for the NINTH ANNUAL NEW YEAR'S DAY RIDE & PARTY that I put on every year.

If you're within a couple hundred miles of Brooklyn, you should come out. It's a fine tradition and a good time. Rain, shine, snow, sub-zero temps, no excuses. We have pictures of bikes parked in sidewalk snow drifts.

Jason

December, 2005

Pics:

Here's the offending inserts. A couple cases of this on both heads.

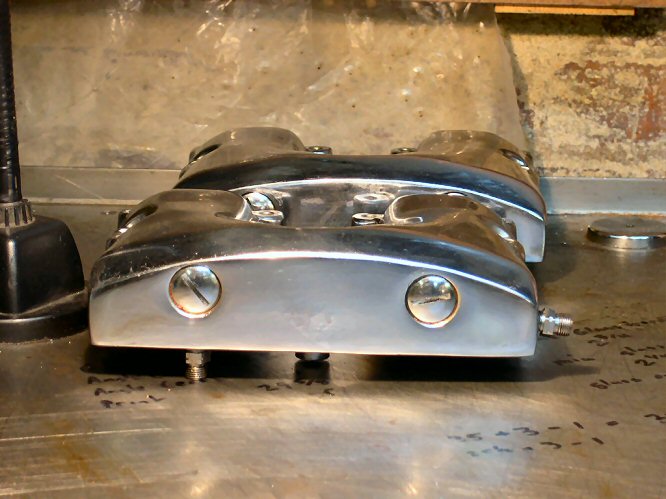

Rocker boxes from the parts stash.

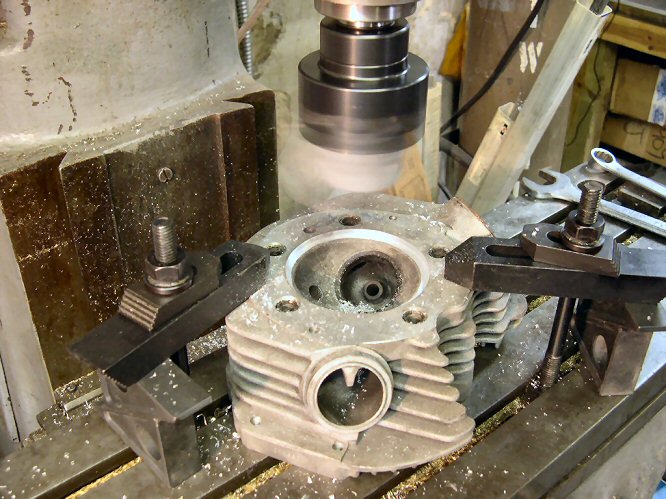

Locating the head gasket plane to be perpendicular to the spindle axis.

Locating the head bore on center with the spindle.

Somewhere in the middle of the handful of cuts taken.

Bores finished. Came out nice for using an $80 Kung Pow boring head.

Test fitting the heads on the cylinders. Fire ring O.D. was 3.880. I cut the heads to 3.884 to leave a little room.

Lapped the valves.

Lapped the valve seats.

Valves installed in head.

Almost finished. It's late and I have to get to work tomorrow early. Gas tanks and test fire are the only things remaining to do.

This motor is on deck for my next project. I just finished building up that wheel on an OLD star hub (converted to Timken bearing though).

More tech articles @ www.greasygringo.com